Dry self-priming universal pump for many liquids

Impeller pumps by ZUWA are especially easy to maintain and cheap to run. Thanks to the flexible impeller the pumps are capable to move solid content or convey highly viscous fluids.

The running wheels (flexible impellers) in our impeller pumps are available in different, always flexible materials to meet the requirements of many fluids. The impellers are not arranged centered in the elliptical housing. Due to the rotation of the impeller and therefore the bending of the impeller's blades a vacuum is created which sucks in the liquid. Because our impeller pumps are self-lubricating, only a rather short dry run is possible. After utilisation a longer dry-run is possible, but not recommendable.

ZUWA impeller pumps are available in several sizes with several drives and are made drom stainless steel, aluminum or plastic. We provide impellers made from NBR, EPDM, CR, FKM, FPM and TPU.

Our impeller pumps can be used with different drives: electric motors, air motors, belt drive, hydraulic motors, with a power drill or a cordless drill with an adapter.

How does a flexible impeller pump work?

The flexible impeller turns within an eccentrically formed casing creating a suction via the flexing of the impeller blades, which draws the fluid into the pump casing. The medium itself acts as a lubricant between the blades and the casing, therefore minimizing friction and allowing smooth fluid transfer. In order to avoid possible damages to the pump it is recommended to install dry run protection to each flexible impeller pump by ZUWA.

1. Suction

On the suction side the blades begin to straighten. The chamber space between each blades enlarges and creates a vacuum pulling the fluid into the pump.

2. Transfer

With the turning of the impeller the fluid is positively displaced from the inlet to the outlet. Small particles are also able to be pumped freely through the chambers.

3. Pressing

On the pressure side the blades of the impeller begin to flex causing the chambers to shrink, therefore forcing the fluid in a constant flow out of the pump.

The advantages of an impeller pump

Dry self priming

What makes impeller pumps outstanding – they do not need to be fi lled prior to operation. Impeller pumps are dry self priming from a depth of three meters. Pre-filling is required for a suction depth of three metres and more. The suction depth is max. 7 metres.

High capacity

Depending on type and model our pumps are capable of transferring from between 3 litres up to 730 litres per minute. Tanks will be drained down to the last drop.

Versatile

Useful for many different fluids and applications. Materials of impellers, seals and pump housings can be selected according to the individual needs and applications required.

ZUWA Impeller Pumps are available with AC and DC motors with various revolutions per minute.

Gentle

Fluids are transferred absolutely free of pulsation. Smaller amounts of air or other gaseous fluids can be handled on the suction side.

Reliable

All pumps are tested for continuous operation in our workshop. Top quality materials guarantee for a long durability.

Easy maintaining

For cleaning and maintenance work the pumps are quickly and easily disassembled. Replacement parts can be ordered individually. Low operation costs!

Sturdy

Impeller pumps will readily pump fluids with a wide range of viscosity, even highly viscous liquids such as oil or honey (up to 20 000 mPAS) as well as liquids containing solids.The approved media temperature is max. 90°C. A short dry-run of up to one minute can be tolerated.

Where impeller pumps are being used

Impeller pumps offer a wide range of options. Therefore you can offer individual pumps for you own requirements.

ZUWA pumps may be found operating in the following applications:

- Ship building

- Biotechnology

- Heating and sanitation

- Electroplating and workshop

- Agriculture and gardening

- Water and waste water treatment

- Beverage and food industry

- Industrial, mechanical, plant engineering

- and many more

For all applications the right impeller material

NBR /Acrylonitrile-Butadiene-rubber (Perbunan®, Buna-N®):

For water, antifreeze, heat transfer fluid, vegetable oil and grease high impact elasticity and good mechanical strength good for applications involving high pressures up to max. 5 bar.

EPDM /Ethylene-Propylene-Diene-rubber (Keltan®, Buna EP®):

For hight temperatures, for acids and bases. high elasticity and very good mechanical stability.

CR /Chloroprene-rubber (Neoprene®, Bayprene®):

Preferably used for applications in the food industry. flame retardant, tearproof, durable.

FKM or FPM /Fluor-rubber (Viton®, Fluorel®):

For oil, diesel, fuel oil, palm oil, soy bean oil and oil emulsive wood preservatives very good chemical resistance, less mechanical resistance.

Plastic:

For water, mineral and vegetable oils, diesel fuel, heat transfer fluid and several chemicals. Extremely tear resistant and good mechanical resistance (not suitable for abrasive fluids) maximum fluid temperature 60°C.

Pump types

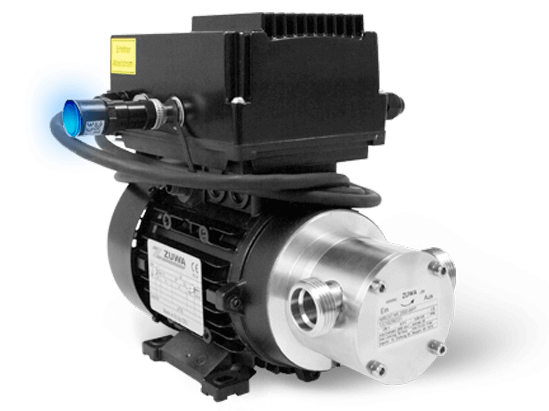

UNISTAR

A multi-purpose pump designed for transferring clean or contaminated fluids. Not suitable for handling abrasive or corrosive fluids.

COMBISTAR

Particularly suitable for all fluids types containing abrasives. It is an economic alternative to the NIROSTAR series pump for transferring abrasive or slightly corrosive fluids.

NIROSTAR

A high quality stainless steel pump for use in various applications within industrial plants and production facilities. The appropriate choice for transferring corrosive fluids.

ACOSTAR

The synthetic impeller pump for a wide variety of applications in the chemical sector. Perfect for fluids with various viscosities, aggressive acids, bases, and solvents.

Iimpeller pumps in detail

Impeller pump with motor

Impeller pump without motor